Recent searches

Search options

#lasercutting

#homelab #minirack #projects #lasercutting #3dprinting

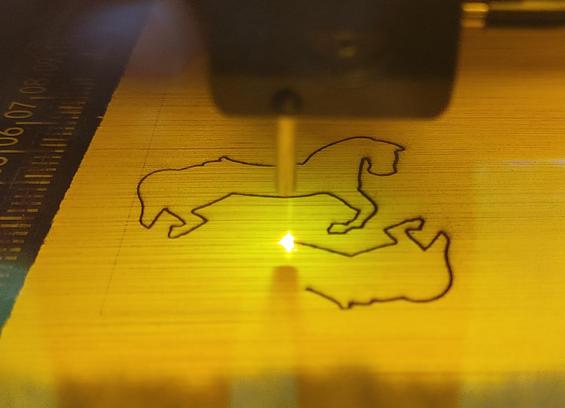

Meine Partnerin hat wieder ein paar Sachen gemacht. Das hier ist Hercule. Sie hat ihn gezeichnet, in eine Datei für den Laser umgewandelt und nun ist er hier. Willkommen in der Familie.

Related: since the actual time they have for this at school is limited, I'm helping out with preparations.

They're going to make a merry go round (with rotating mechanism)

#lasercutting

Made a laser crafted sign to go outside the laser room of my local makerspace. Very happy with how it turned out. I did a blog post over on Maker Forums on the make. (see link)

https://forum.makerforums.info/t/makerspace-laser-room-sign/92959?u=nedman

Curb find Confucius dropping some pearls of wisdom for current times.

#SignalGate #CurbFind #Confucius #LaserCutting

@reckter @pastagang

Made some pastagang tshirts!!!

Will bring them this Wednesday. I’ve made 6, different sizes

Made a new front panel for the door opener system at Blender HQ.

Designed with Blender & Inkscape, using my add-on Flatterer of course!

I just released a new version of my Blender add-on Flatterer. It's my go-to tool for my laser cutter projects.

It has a bunch of fixes, and some quite useful operators for adding boolean operators (cut selected out of active, and cut active out of selected objects).

.

..

...

#caturday #catlady #catlover #kattenkop #kattensieraad #kattenshop #catshop #etsynl #etsyseller #handmadewithlove #handmadejewelry #handgemaaktesieraden #smallbusiness #kleinbedrijfje #shopsmall #kat #gato #chat #lasercutting #kattenvrouwtje

Meine Partnerin hat heute was entworfen und gefertigt.

Servus Wolfgang, und willkommen in unserer Herde.

—

My girlfriend designed and made a thing.

Hi Wolfgang, and welcome to our herd.

I also like doing stuff like this where a sketch solves for a messier relationship: here, two ball bearings are sandwiched on each side of a lasercut segment. The hole they both seat into takes into account the material thickness so they have a small gap left between and don't crash.

Freshly cut gears from last night’s Weekly Tuesday Open Night at Tog Hackerspace!

I’m always a fan of having built in adjustment tools for things that need to be periodical adjusting. Needing to use the cabinet key to open the bottom door on these bigger laser machines has always bugged me. Finally decided to design and 3D print some knobs with built in triangular keys slots. Friction fit on the triangle so they can be removed if needed.

Apparently these triangular cabinet locks are not universal in the key size as the ones I made for the makerspace machine don't fit my own laser machine. So if you make your own, I would recommend doing some 5mm tall test prints of the cylinder with the triangular holes, all the way through, to fine tune the fit size. The corners of the triangles should be slightly rounded to give more room within the cylinder.

Also added some additional 24v led lighting to the inside of the lid. #MakerSpace #LaserCutting

Spent some time this evening doing a few upgrades. Like adding a solid state relay to control the built in exhaust fan and air assist air pump. That way we can control them from the control panel or through the Lightburn software. #Makerspace #Lasercutting.

My local makerspace has upgraded from a pair of K40 lasers to a very nice 60W Omtech machine.

Finished painting my homemade Carcassonne meeples! A multi-year project. Found some nice varnish based paints for miniatures that had colors close enough to what I had in mind. The meeples are made from lasercut plywood, two 3mm sheets glued together.

Having a laser cutter is great for rapid prototyping.

I needed a generator interlock plate for my power panel, but I wasn't able to find one with the right configuration.

A bit of measuring and I designed a prototype which I've temporarily fashioned from cardboard as I tweak the final dimensions.

#LaserCutting #maker #prototyping